The Canadian Building Codes allow a couple of methods for determining fire-resistance ratings of assemblies, from Article 3.1.7.1.:

- Tests conducted in conformance with CAN/ULC-S101 (usually demonstrated through a UL or other listing)

- Appendix D of the Building Code

It is important to note that the fire & sound resistance tables from Part 9 (Tables 9.10.3.1.-A and 9.10.3.1.-B) cannot be used in Part 3 buildings for assigning fire-resistance ratings. They can be applied for assigning Sound Transmission Class only in Part 3 buildings.

Designers who are used to applying the Part 9 tables for assigning fire-resistance ratings sometimes have difficulties when trying working on Part 3 buildings. This post provides a high level overview of the component additive method (CAM) for wood and steel frame walls, floor and roofs from D-2.3 of Appendix D in the Building Code and some common mistakes.

The fire & sound resistance tables from Part 9 cannot be used in Part 3 buildings for assigning fire-resistance ratings.

Appendix D or a Listing?

The main advantage of using Appendix D for assigning fire-resistance ratings over a listing is that Appendix D uses generic materials, while most listings reference specific proprietary products. When applying Appendix D, Type X gypsum board means any product that meets the special fire-resistant board requirements from CAN/CSA-A82.27-M or ASTM C1396/C1396M. Understanding the details of these standards are most likely not important for applying Appendix D, but the gypsum board product sheets will indicate if the product meets Type X based on one of these standards if there is any uncertainty.

Listings, in contrast, often reference specific products from various manufacturers. Since products are generally not specified on architectural drawings, this can lead to discrepancies between design and installation, which could void the listing.

How to Use Component Additive Method

Fire-resistance ratings using the CAM are assigned by adding times assigned to each component in the assembly:

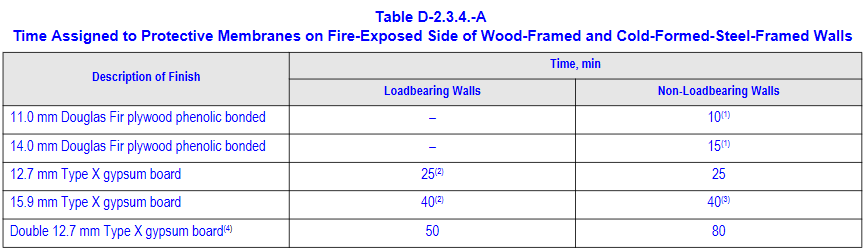

- Membranes on fire exposed side (Table D-2.3.4.-A for walls, Table D-2.3.4.-B for floors)

- Framing members (Table D-2.3.4.-E for walls, Table D-2.3.4.-F for floors and roofs)

- Additional protection from Table D-2.3.4.-G (e.g. insulation, concrete topping)

It is important to note that interior partitions require a membrane on both sides, but the time for only one side (the fire exposed side) is considered. For asymmetrical assemblies, the lowest time between the membrane(s) on either side of the framing members needs to be used.

Framing members must comply with D-2.3.6, which includes minimum size requirements (e.g min. 2×4 for wood studs, min. 2×8 for solid wood joists).

Keep in Mind…

Here are a few notes to remember before you try to define an assembly using the CAM:

- Maximum 90 min fire-resistance rating

The CAM method in D-2.3. of Appendix D can only be used to assign ratings up to 90 min. If you require a rating over 90 min, you will either have to use a listing or a different type of assembly (not wood or steel frame). Appendix D can assign ratings in excess of 90 min for other types of assemblies, such as concrete walls or floors,

2. Fire-resistance rating cannot be increased by adding additional membrane layers

Multiple layers of membranes can be used in assemblies; however, the rating assigned to the assembly would be based on a single layer only, unless the table being applied specifically mentions multiple layers. For example, Table D-2.3.4.-A (see below) assigns a 50 min rating for double 12.7 mm Type X in a loadbearing assembly. Two layers of 15.9 mm Type X can be used; however, the rating assigned to the membrane would only be 40 min.

It is common to provide additional layers of drywall to increase the STC of an assembly, or plywood for structural purposes. Both are acceptable provided the membrane fastening requirements in D-2.3.9. are still met and no additional time for the additional layers are assigned.

3. Times assigned are not the fire-resistance ratings of individual components

The CAM assumes a full assembly with certain constraints. For interior fire separations, this would consist of a membrane on each side of framing members. For floor assemblies, the assembly would consist of a membrane on the underside of framing members and a subfloor on top. If any of these components is omitted, no fire-resistance rating can be assigned.

The times assigned to membranes in the CAM are not the same as “finish ratings” sometimes cited in listings. The times assigned to membranes are based primarily on their ability to remain in place during fire tests. A fire-resistance rating, however, also includes a temperature rise limitation criteria. The temperature rise criteria is not accounted for in the times assigned to components in Appendix D, as it relies upon the entire assembly to meet the criteria. Finish ratings provided on listings account for the temperature rise criteria and can be considered as the fire-resistance rating provided by the finish/membrane only in an assembly.

8 Responses

Hey Marc

Thanks for sharing your knowledge and clarification using the Component Additive Method.

I am a Part 9 Inspector but often find myself looking into Part 3 for different applications and compare differences.

One Questions: Is there a Code reference that would direct me to allow the use of the Sound Class info for Part 3 buildings

Thanks

Hi Dave, thanks for commenting.

Sentence 3.3.4.6.(1) refers to Section 5.8. for sound transmission and dwelling units (Part 3 buildings also need to comply with Part 5). Sentence 5.8.1.3.(1) states that compliance with the required STC ratings can be demonstrated through the use of assemblies conforming to Tables 9.10.3.1.-A or 9.10.3.1.-B.

Hope this helps.

Hi Marc,

Another great post! I always found it odd that there isn’t a rating in Table D-2.3.4.-A for double 5/8″ Type X gypsum board, only double 1/2″. I don’t know how it is in Victoria and the Lower Mainland but around here 1/2″ Type X is rarely used – everyone seems to go with 5/8″ even if it’s more than what they need. Double layering of 5/8″ Type X is all over the Part 9 tables so it seems strange to me why they wouldn’t include it in the Appendix D table. Is it simply because they do not want to commit to any rating larger than 90 minutes for Part 3 buildings unless it’s been proven (i.e. tested to CAN/ULC-S101)?

Thanks Nelson. 1/2″ Type X is not readily available to my knowledge either. Type C seems to be used if a 1/2″ fire rated drywall is required (Type C meets the requirements of Type X).

I am not sure on the reason for limiting the assemblies to 90min. It could be simply limitations on the tests that were performed in developing the component additive method. I know that not all assemblies in the Part 9 tables were tested, and the fire-resistance ratings for some assemblies were extrapolated based on similar wall assemblies. The CAM is likely more conservative in this regard, but I am speculating. There is some good background information in this document published by the Canadian Wood Council, though some of the info is dated: https://cwc.ca/wp-content/uploads/publications-FireSafetyDesign-s.pdf

In my experience, additional layers of drywall can be added to assemblies when using Appendix D, but no additional contribution to the FRR of the assembly is added. For example, you might have an assembly with 2 layers of 5/8″ Type X on each side of wood studs (400mm o.c.), but this would still only achieve a 1h rating using the CAM. The additional layers of drywall are beneficial in meeting the required STC rating.

Hi Marc,

Thanks for the post and follow up comments. This one, like many others on this site are a great resource and provide lots of insight and learning opportunities.

There is one comment, which basically confirms your intuition above regarding the 90 min restriction within the Appendix D Background Information; “The fire-resistance rating has been limited to 1.5 h as this method of developing ratings for framed assemblies was new and untried. Although this is the subject of current review, no decision has been made to extend the ratings beyond 1.5 h”.

Thanks for this very nice article I really got so many ideas. I hope you just continue to make articles like this that are very helpful.

Can metal stud replace wood stud for 20 min. allotted in the CAM?

No, it cannot. Steel stud has its own time assigned to it (10 min). It is lower than for wood.